Sailboat Rigging

Marine rigging is a crucial aspect of any sailing vessel, providing the structural support needed to hoist, control, and adjust sails efficiently. Proper rigging ensures that a sailboat remains stable, maneuverable, and able to perform optimally, whether cruising, racing, or navigating through challenging weather conditions. At the heart of marine rigging are two primary components: the standing rigging and the running rigging. Standing rigging refers to the fixed components that support the mast, such as shrouds, stays, and masthead fittings, which are designed to keep the mast in place and maintain the boat’s structural integrity. These components must be made from strong, durable materials like stainless steel, Dyneema, or carbon fiber to withstand the forces experienced on the water, including wind, waves, and tension from the sails.

Running rigging, on the other hand, includes the lines, blocks, and winches that allow sailors to control the sails during operation. These include halyards, sheets, and reef lines, which are essential for adjusting sail trim, raising or lowering sails, and controlling the boat’s speed and direction. The running rigging is typically more flexible and can be made from materials like braided polyester, aramid fibers, or Dyneema, offering both strength and flexibility for smooth operation. Blocks, cleats, and winches are important pieces of marine rigging hardware, providing sailors with the mechanical advantage needed to handle the powerful forces of the wind and trim the sails with precision.

One of the most vital aspects of marine rigging is ensuring that all components are properly maintained and inspected. Regular checks for signs of wear, such as fraying lines, rusted shackles, or loose fittings, are essential for maintaining the safety and performance of the boat. Rigging inspection is especially important after long voyages or during heavy weather conditions, as even small issues with the rig can lead to major failures. Proper rigging tension is another critical consideration, as it ensures that the boat’s mast is aligned correctly and the sails operate efficiently. Tensioning tools and rigging tension meters are commonly used to adjust the standing rigging, ensuring that the mast is neither too tight nor too loose.

Modern advancements in marine rigging technology have led to the development of high-performance materials and equipment designed to improve the efficiency and safety of rigging systems. For example, carbon fiber and other lightweight materials are increasingly used for mast construction, reducing the weight of the rigging and improving the vessel's overall performance, particularly in racing sailboats. In addition to the materials used, the design of rigging systems has also evolved to optimize sail handling and ease of use. Many racing yachts now feature advanced rigging configurations like in-mast furling systems, hydraulic backstays, and multiple winches, which provide faster and more precise adjustments to the sails.

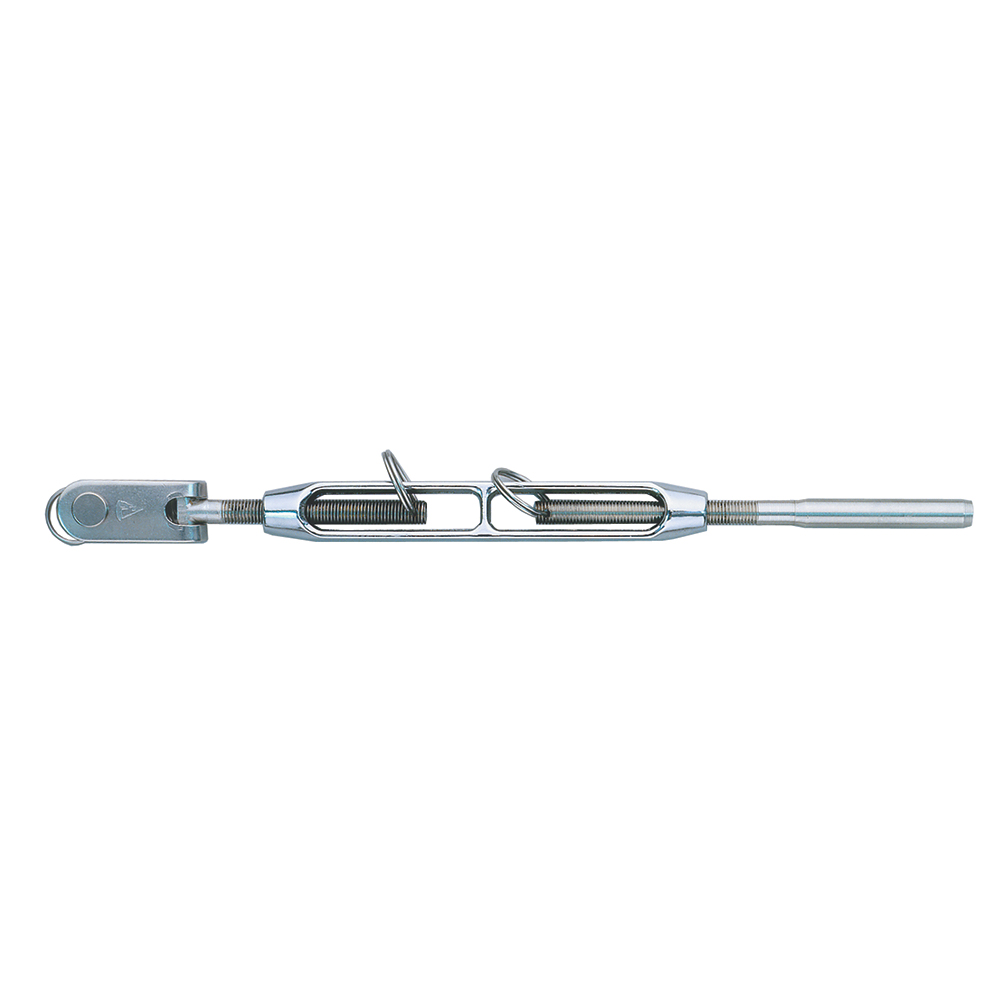

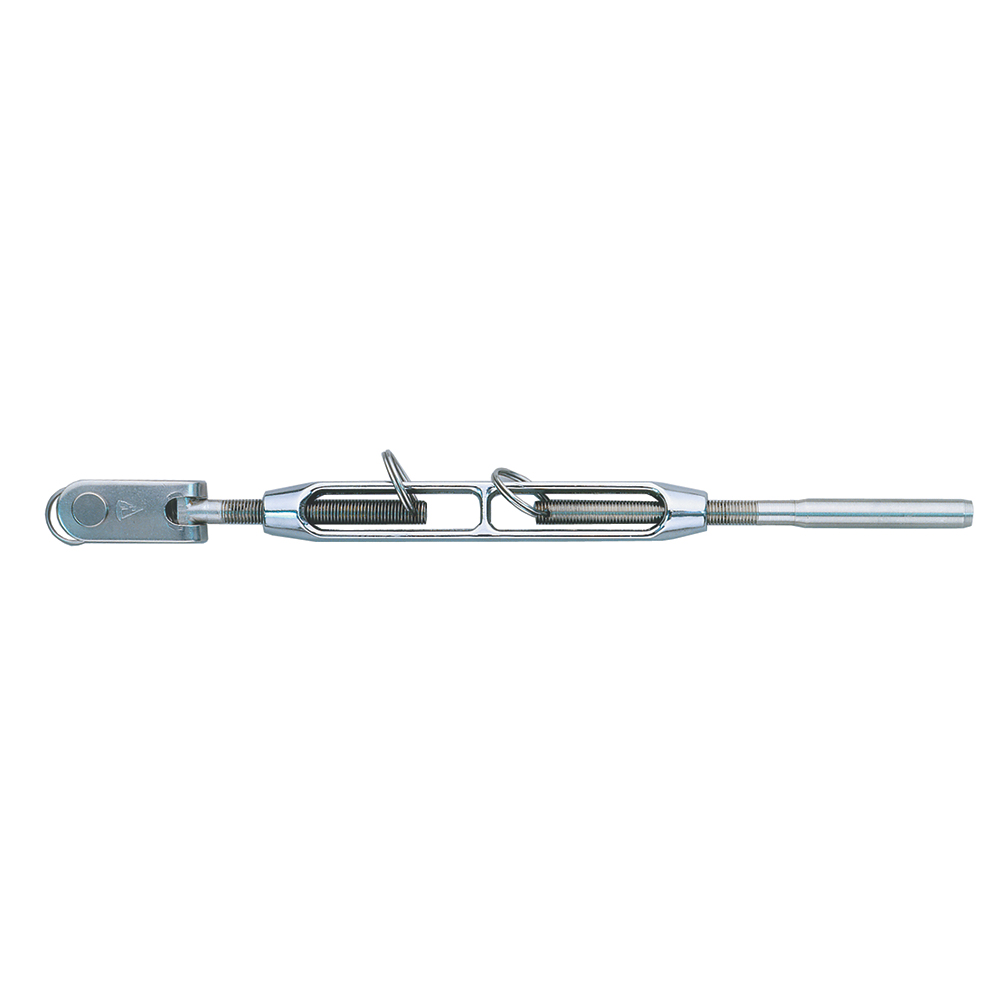

Another important element of marine rigging is the role of the rigging hardware, including turnbuckles, clevis pins, and shackles, which connect various components of the rigging system. These hardware pieces are designed to withstand immense loads while being easy to adjust when necessary. High-quality materials like stainless steel, titanium, and bronze are commonly used for rigging hardware to ensure longevity and corrosion resistance. For offshore and cruising vessels, having robust and reliable rigging hardware is vital for ensuring the safety of the crew and the vessel, as compromised rigging can lead to catastrophic failures.

Marine rigging also plays an essential role in sailboat performance, particularly in racing or competitive environments. Properly tuned rigging allows sailors to adjust their sails for optimal wind efficiency, ensuring maximum speed and maneuverability. Sail trim adjustments, made possible by well-maintained running rigging, allow sailors to fine-tune the boat’s performance based on changing wind conditions, making rigging setup and adjustment critical to success in racing scenarios. The ability to adjust the mast bend, adjust the backstay tension, and use adjusters on the headstay or forestay can significantly impact the boat's performance.

In conclusion, marine rigging is an essential system that encompasses both the standing and running rigging components, each serving a specific function to ensure a sailboat’s performance and safety. From the mast and stays to the blocks, winches, and lines used for controlling sails, every aspect of rigging must be carefully chosen, installed, and maintained to perform optimally. The quality and condition of rigging hardware and materials play a direct role in the boat's ability to handle harsh marine environments, providing stability, maneuverability, and efficiency. Whether cruising or racing, understanding the intricacies of marine rigging and ensuring that all components are functioning correctly is essential for a safe and successful sailing experience.